Your architectural vision deserves the highest standard in curtain wall solutions. As a specialist manufacturer, we engineer high-performance, design-forward curtain walls. From blueprint to build-out, our professional team supplies thorough support to secure outstanding quality and performance.

- Explore an extensive lineup of premium curtain wall systems designed to match project specifications.

- We utilize forefront technologies and top-grade materials to deliver sturdy, enduring curtain walls.

- We copyright eco-friendly manufacturing principles to reduce environmental impact across our processes.

Allow us to serve as your reliable collaborator in bringing architectural plans to life. Contact us today to discuss your project and discover the benefits of working with a top-tier curtain wall manufacturer.

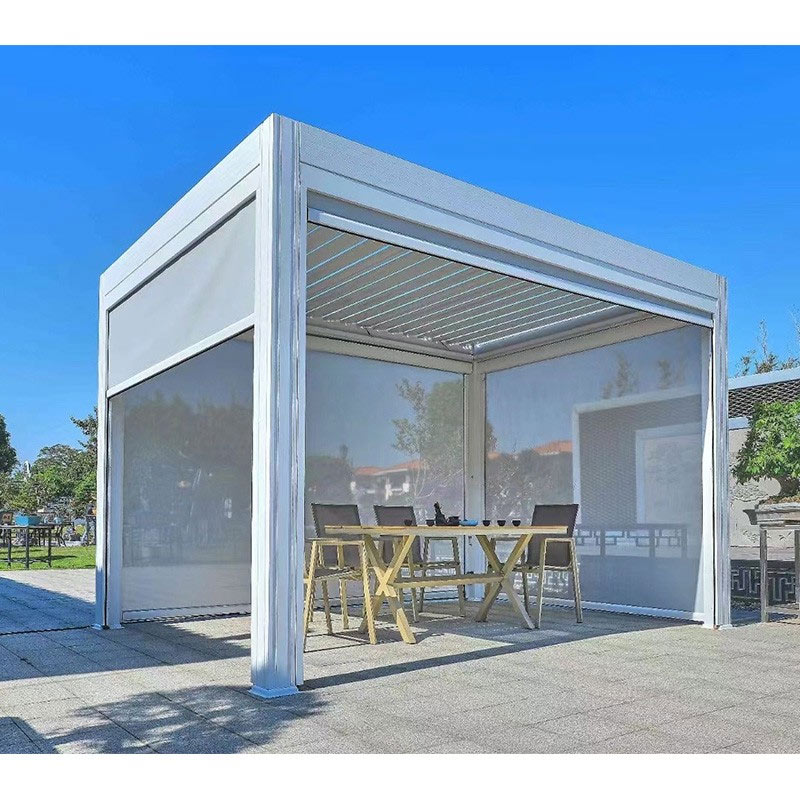

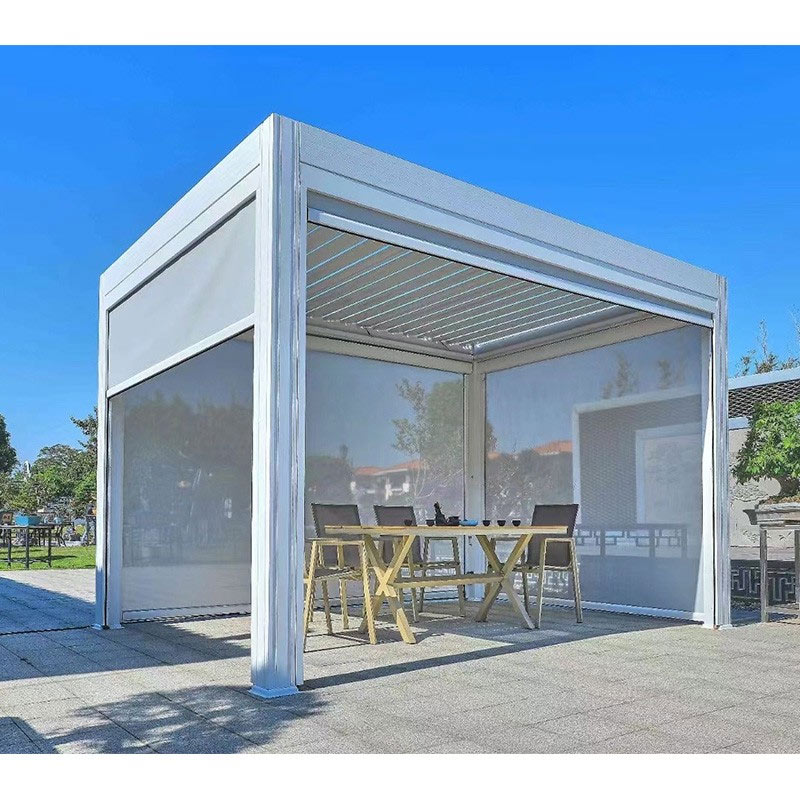

Transparent glass systems that boost aesthetics while delivering high performance: Blending Design Finesse with Reliable Performance

Glass curtain walls have reshaped the built environment by offering unmatched design appeal combined with efficient performance They provide an open, clear connection between interior and exterior, enhancing spatial perception. Comprised of sequential glass panels, they support broad daylighting and interior brightness.

Besides their attractive finish, glass façades contribute significant performance and endurance benefits. They present advanced insulating capabilities that minimize energy demand and emissions. Also, glazed façades demonstrate strong weather resistance and lasting structural stability. Choosing specific glazing, section sizes, and framing configurations lets designers customize both performance and aesthetic outcomes.

Aluminium façades combine robustness, lasting quality, and adaptable aesthetics: Load-Bearing Capacity, Extended Durability, and Design Agility

These façades modernize structures through streamlined appearance and engineered resilience. Because aluminum is both light and strong, it supports large glazed areas and offers enduring, flexible design possibilities.

Designed for climatic resilience, aluminium curtain walls resist rust, color degradation, and physical wear.

The formability of aluminium supports bespoke profiles, curved surfaces, and inventive façade solutions.

They support building energy strategies by enhancing thermal regulation and thereby decreasing lifetime operational costs.

A variety of finish options—from matte or satin powder-coats to anodized treatments—enable seamless architectural integration.

Chinese firms in the curtain wall space are notable for their innovative engineering and quality focus

China’s curtain wall industry is undergoing strong growth propelled by demand for modern architectural solutions.

They adopt tough quality assurance practices to maintain product performance and reliability.

Ongoing research initiatives at many firms are driving the development of better-performing curtain wall products.

This R&D focus leads to the creation of advanced materials, system designs, and fabrication technologies.

Such innovation enables manufacturers to deliver curtain walls that are visually striking as well as highly functional.

A defining trait of many Chinese manufacturers is adaptability and the ability to customize solutions for unique projects.

Partnership with architects and developers enables the delivery of curtain wall systems aligned with original design goals.

Tailor-Made Curtain Wall Solutions Crafted for Your Architectural Goals Adjusted to Meet Your Project Brief

We convert design ideas into reality with our specialized bespoke curtain wall systems. Each project receives dedicated custom design attention to ensure the curtain wall complements the overall vision. From modern to traditional expressions, our team partners with clients to ensure curtain walls meet both functional and aesthetic targets.

- Employing contemporary technologies and proven methods, our curtain walls achieve resilience and energy performance.

- We supply varied material options, finishing treatments and glazing types to fulfill distinctive project demands.

- Receive outstanding build quality, meticulous fabrication and committed service throughout your project.

glass curtain wall

Next-generation glazed façades for contemporary construction

Modern buildings increasingly adopt innovative materials and configurations to create functional, striking interiors.

Advanced glass façades provide an ideal mix of openness and energy-conscious performance.

Many designs feature insulated glazing units with gas inserts to cut heat flow and raise insulation.

Structural elements are optimized for durability to preserve façade integrity under severe conditions.

These curtain walls improve the aesthetic experience through generous glazing and visual cohesion.

- Design-forward façades that create a memorable exterior presence

- Greater energy savings accomplished with high-tech glazed systems

- Top-tier thermal performance for consistent comfort and cost savings

- Proven longevity and strength to withstand adverse climatic conditions

- Expanded daylight access to enhance interior vibrancy and occupant wellbeing

Aluminum’s versatility as a material for refined curtain wall systems

Its lightweight strength is why aluminium is a leading material choice for curtain wall engineering The material’s lasting quality and lightweight build let designers craft modern, enduring façades.

Architectural curtain walls commonly use aluminium elements together with glazing and other materials.

Customization supports outcomes from restrained, minimalist designs to richly detailed configurations.

Curtain wall engineering focused on sustainable construction

Curtain wall systems are key to modern buildings, uniting visual appeal and structural function But traditional methods of production may lead to increased environmental burden. Resource-efficient curtain wall engineering reduces ecological footprint by using greener materials and processes.

Sustainable material selection underpins responsible curtain wall engineering decisions. Adopting recycled glass, reclaimed wood and certified bamboo reduces the ecological footprint of curtain wall projects.

Energy efficiency measures are a core component of sustainable curtain wall engineering.

- Eco-focused engineering values longevity and reduced repair cycles to extend building lifespan.

- Embracing sustainability allows the creation of energy-efficient and environmentally considerate buildings.

Seamless integration of aluminum curtain walls with building façades

Modern design calls for façade solutions that balance striking aesthetics and operational efficiency Aluminum curtain walls are a leading choice for façades because they offer multiple benefits that support the broader design intent.

- These systems accommodate multiple glazing options to tune daylight penetration and visibility.

Overall, aluminium curtain walls provide an effective union of style and performance for building exteriors.

Exploring the appeal and performance of glass curtain walls

Glass curtain walls have become widespread in contemporary architecture, combining visual elegance with pragmatic use They grant occupants panoramic views, improved daylight and a perception of larger interior volume.

- With aluminum or steel framing, these walls achieve high structural performance and long service life

- Progress in glass tech yields glazing that boosts thermal efficiency, lowers noise and improves safety

China’s curtain wall manufacturers help set international direction in façade technology

The industry in China has developed strongly, emerging as a major global supplier of curtain wall systems.

This growth is supported by public investments in infrastructure and increasing demand for sustainable façades.

Chinese manufacturers are recognized for their dedication to producing curtain walls that meet international standards.

Investment in research infrastructure strengthens the industry’s technological advancement.